Solution de robotique en fonderie

Solution de robotique en fonderie :

1, Efficacité accrue : la robotique dans les fonderies peut considérablement améliorer l’efficacité en automatisant des tâches telles que la manipulation des matériaux, le coulage et la finition. Les robots peuvent travailler à un rythme constant, sans interruption ni fatigue, ce qui accélère la production et réduit les temps de cycle.

2, Sécurité améliorée des travailleurs : les opérations de fonderie peuvent être dangereuses, exposant les travailleurs à des températures élevées, à des équipements lourds et à des matières dangereuses. L'utilisation de robots dans l'industrie de la fonderie peut contribuer à minimiser ces risques en effectuant des tâches dangereuses, réduisant ainsi le risque d'accidents et de blessures pour les travailleurs humains.

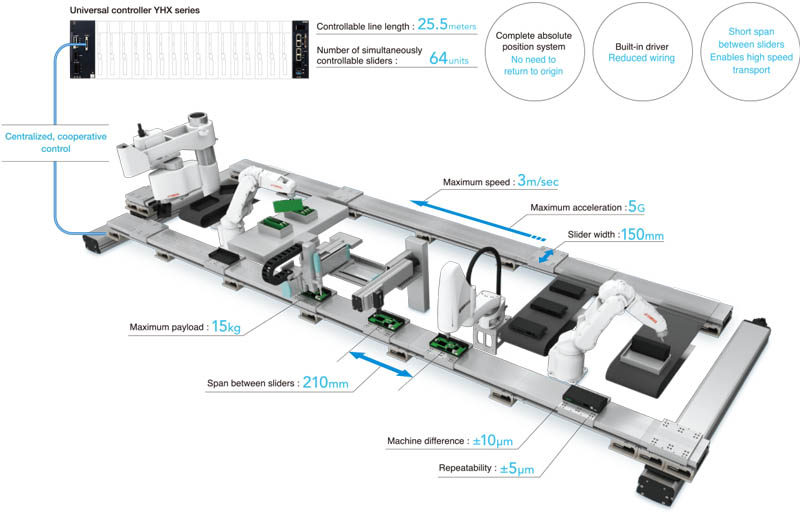

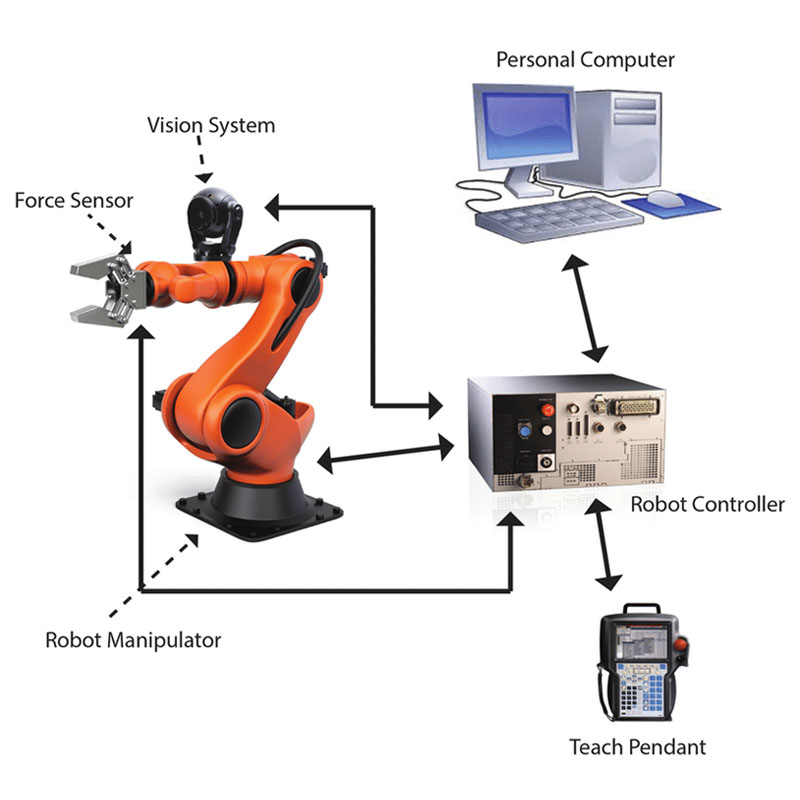

3, Précision et exactitude améliorées : les robots des fonderies peuvent effectuer des tâches avec un haut niveau de précision et d’exactitude. Ils peuvent verser avec précision du métal en fusion dans des moules, manipuler et positionner les pièces de manière cohérente et effectuer des tâches de finition complexes. Cela se traduit par une qualité de coulée améliorée et réduit le risque de défauts ou d’incohérences.

Veuillez nous contacter pour les paramètres techniques détaillés.

Solution de robotique en fonderie :

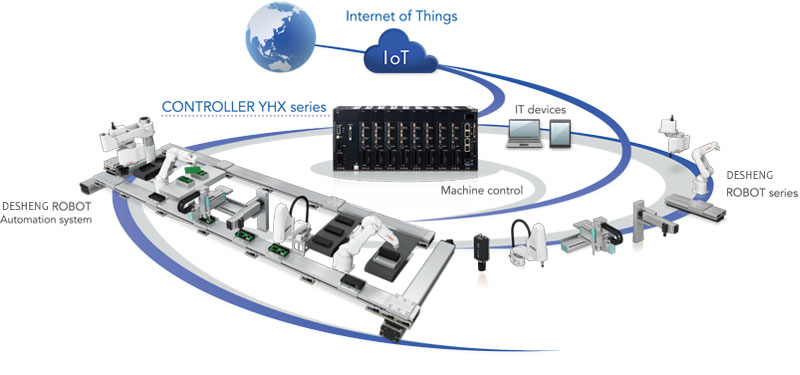

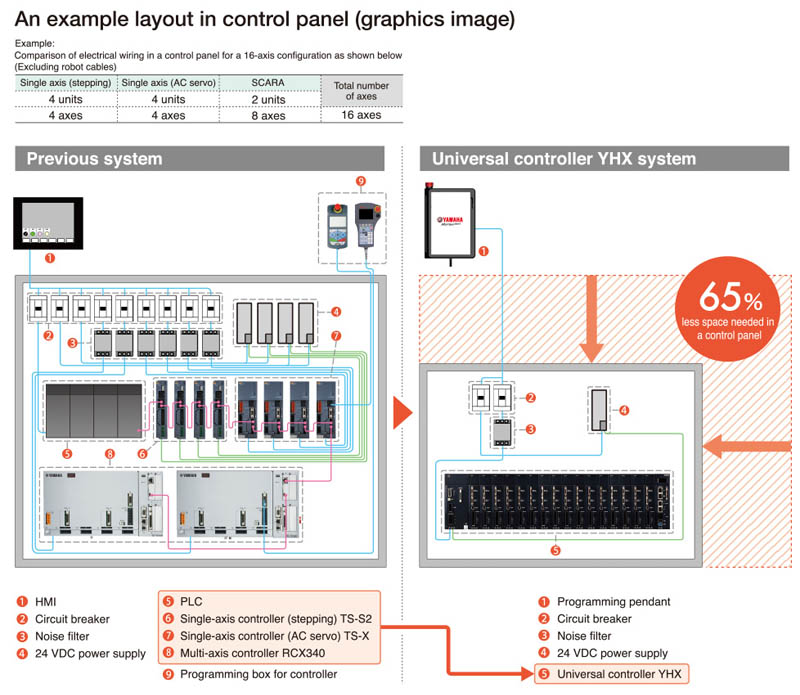

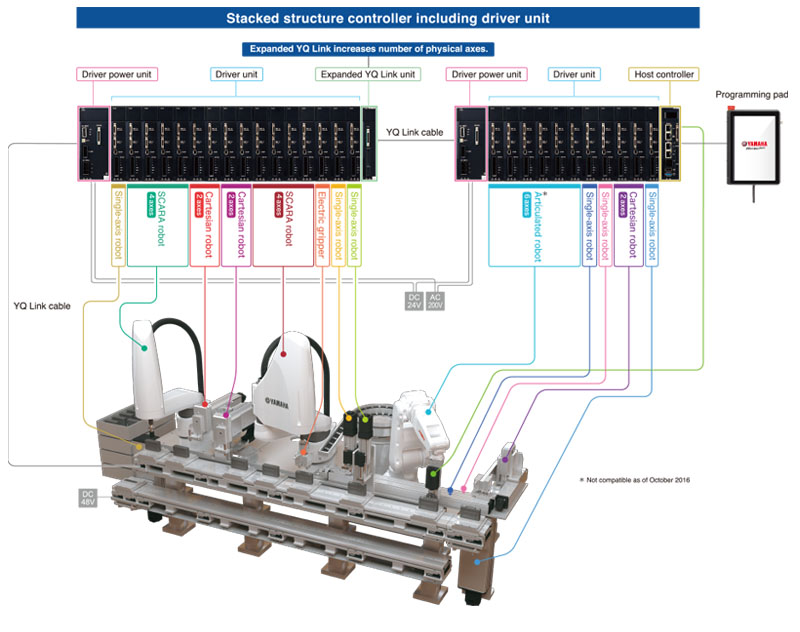

La robotique dans les applications de fonderie a révolutionné l'industrie manufacturière. Solution de robotique en fonderie dans notre entreprise peut économisez 92 % sur le coût d'une patrouille habitée. Veuillez nous contacter pour les paramètres techniques détaillés. Les robots sont utilisés pour des tâches telles que le moulage, le moulage et la finition, réduisant ainsi l'implication humaine et augmentant l'efficacité et la précision. Ils peuvent résister à des conditions difficiles, notamment des températures élevées et de la poussière, garantissant ainsi une qualité de production constante. Les robots améliorent également la sécurité en effectuant des tâches dangereuses, minimisant ainsi les blessures sur le lieu de travail. De plus, ils sont programmables et peuvent être personnalisés pour répondre à des exigences de production spécifiques. Cette technologie d'automatisation réduit les coûts opérationnels et augmente la productivité, ce qui en fait une partie intégrante des fonderies modernes.