Solution robotique de fonderie Abb

Solution robotique de fonderie Abb :

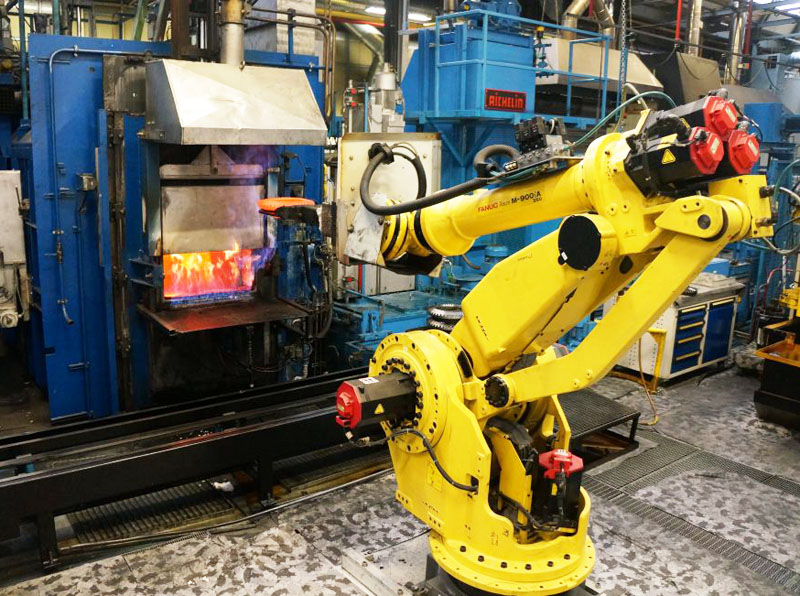

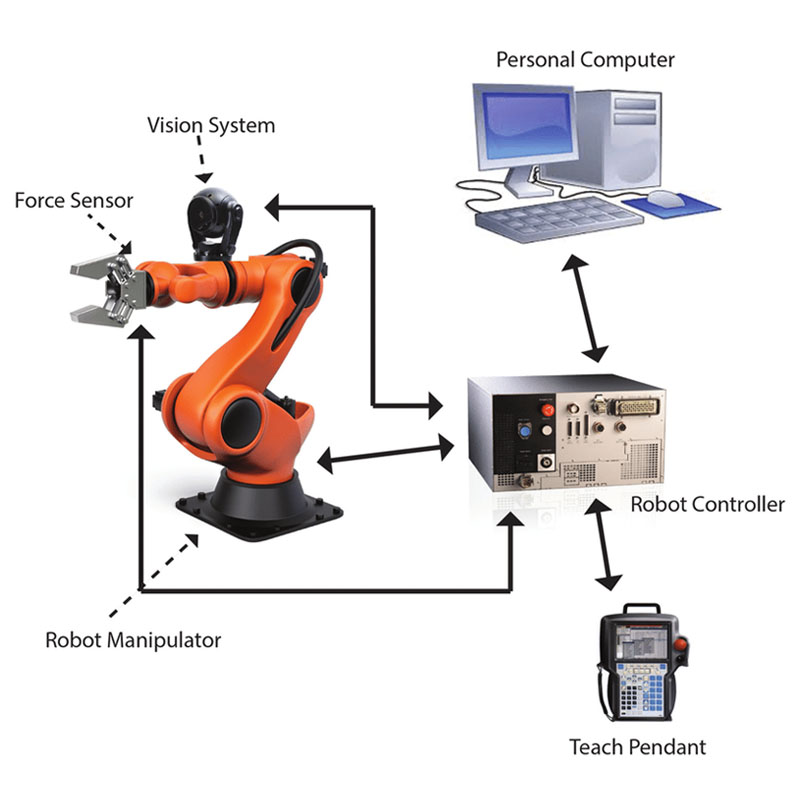

1, Capacités d'automatisation avancées : les robots de fonderie ABB sont équipés de capacités d'automatisation avancées, leur permettant de gérer des tâches complexes avec précision et exactitude. Ils peuvent effectuer des tâches telles que couler du métal en fusion, manipuler des composants lourds et manipuler des moules avec facilité.

2, Sécurité améliorée des travailleurs : les robots de fonderie ABB contribuent à minimiser les risques pour les travailleurs humains dans les environnements de fonderie dangereux. Ils peuvent effectuer des tâches à des températures extrêmes, travailler dans des espaces confinés et manipuler de lourdes charges, réduisant ainsi le risque d'accidents et de blessures.

3, Productivité et efficacité améliorées : les robots de fonderie ABB améliorent considérablement la productivité des opérations de fonderie. Ils peuvent travailler en continu sans interruption, ce qui entraîne une augmentation des cadences de production et une réduction des temps de cycle. Leurs mouvements rapides et précis permettent un flux de travail efficace et optimisé en fonderie.

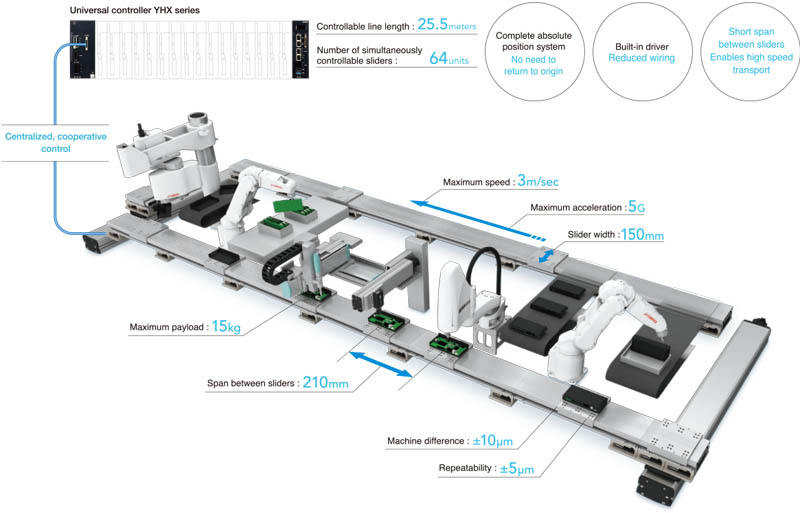

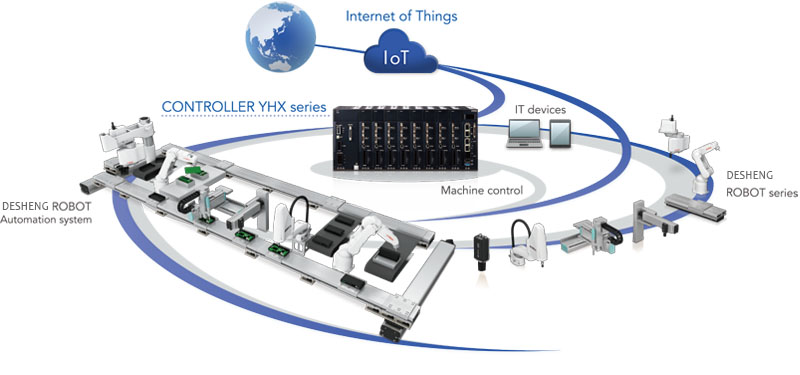

Veuillez nous contacter pour les paramètres techniques détaillés.

Solution robotique de fonderie Abb :

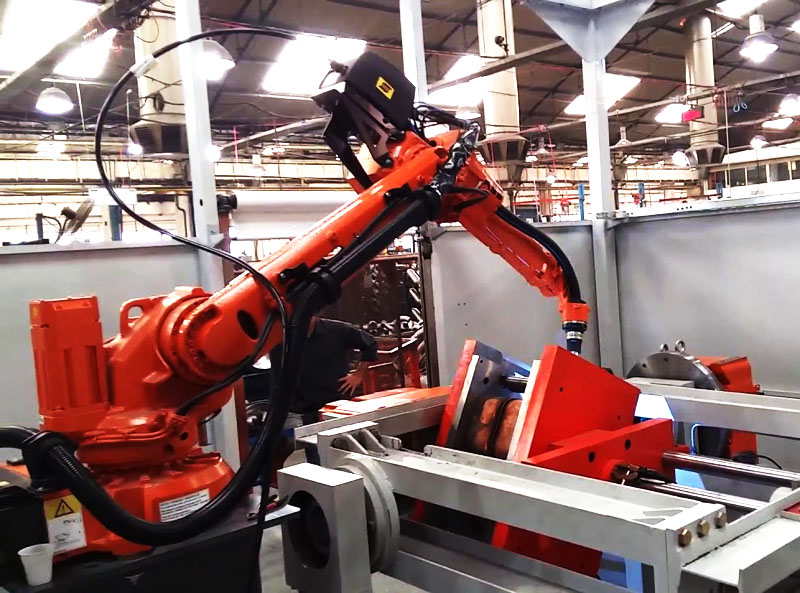

Les robots de fonderie ABB sont principalement utilisés dans les industries pour des tâches telles que la manutention des matériaux, l'entretien des machines, le moulage, le moulage sous pression et le soudage par points. Ils sont conçus pour résister aux environnements difficiles et à haute température. Ces robots augmentent la productivité, améliorent la qualité et renforcent la sécurité sur le lieu de travail. Ils sont également utilisés dans l’industrie automobile pour des tâches telles que l’assemblage, la peinture et le soudage. Les robots de fonderie ABB sont également capables d'effectuer des tâches plus complexes, telles que l'impression 3D, avec précision et exactitude. Ils sont conçus pour être flexibles et polyvalents afin de s'adapter à une variété d'applications industrielles.